Our industry solutions

Whether wind power, railroad technology, laser technology, LEDs, solar applications or converters – we will be happy to share our knowledge regarding the economical design of thermally optimized heat sinks with you. We will provide industry-specific advice to help you find the right dimensioning for your heat sinks.

Wind power

Heat sinks from Seifert electronic are used in wind turbine assemblies. In control systems for blade adjustment and wind tracking, they are used as heat sinks for wind power. In addition to their cooling function, heat sinks for wind turbines must also meet the requirements for increased corrosion protection, long-term reliability and low maintenance. The Seifert high-performance profile and finned heat sinks reliably protect the inverters and frequency converters in wind turbines from overheating.

Railroad technology

Optimum utilization of the available installation space, maximum safety and dependability and durability are the high requirements that our heat sinks meet when used in railroad technology. Heat sinks used in railroad technology are often push-through versions, where the cooling fins are inserted through a housing cut-out and exposed to the airflow in this way. To protect them from environmental influences, the electronics are kept on the cooler base surface located on the inside. The electronics are partitioned off from the outside using seals. Seifert electronic is certified in accordance with EN 15085 for the supply of welded heat sinks.

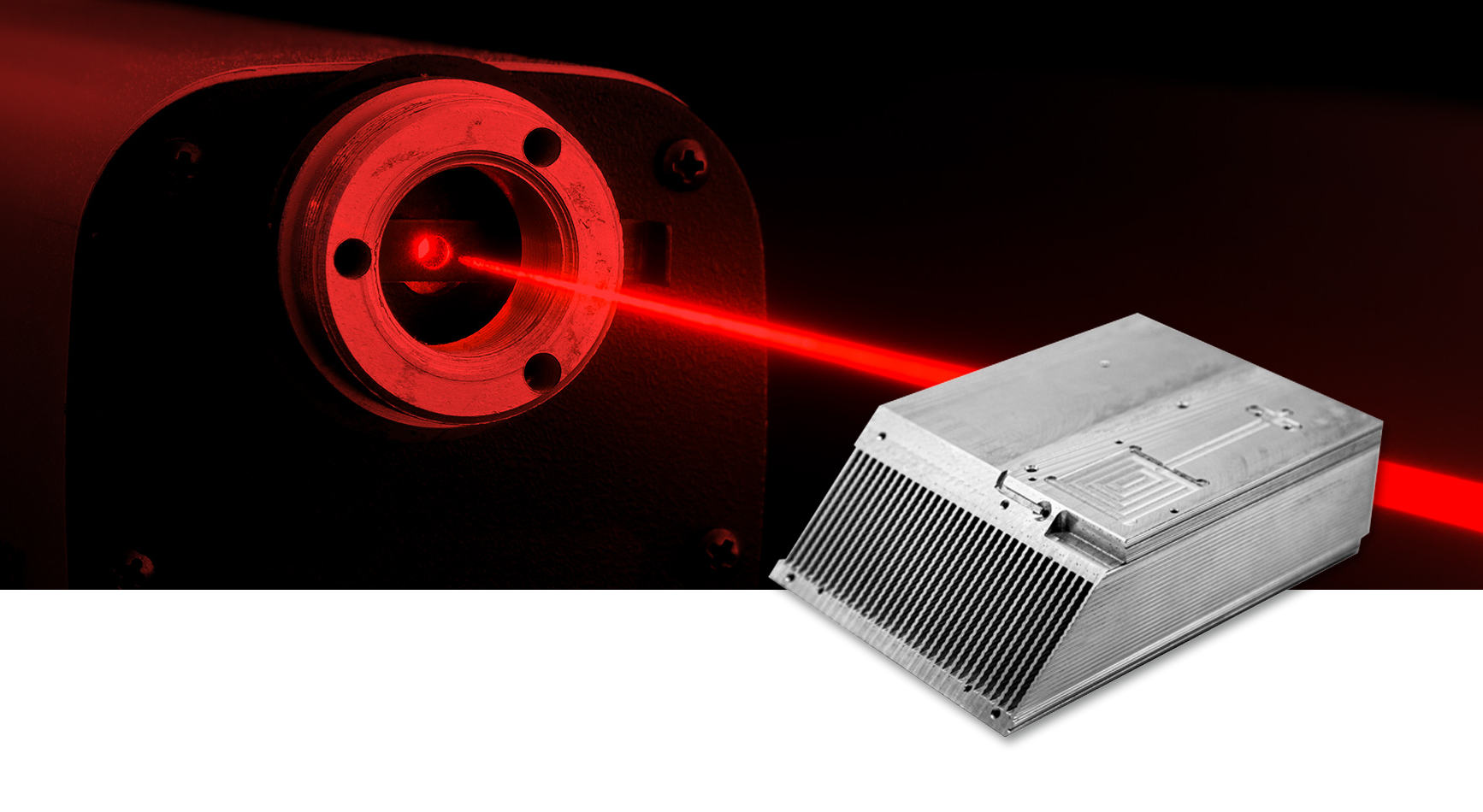

Laser technology

Modern laser systems have now become indispensable in metal processing, medical technology, telecommunications, microprocessing, inscriptions and much more. Heat sinks for forced cooling are used to cool the laser devices. A particularly high level of heat dissipation is achieved here by means of turbulent flow. In laser applications, Seifert heat sinks often combine the actual cooling task with other functions such as fastening or housing.

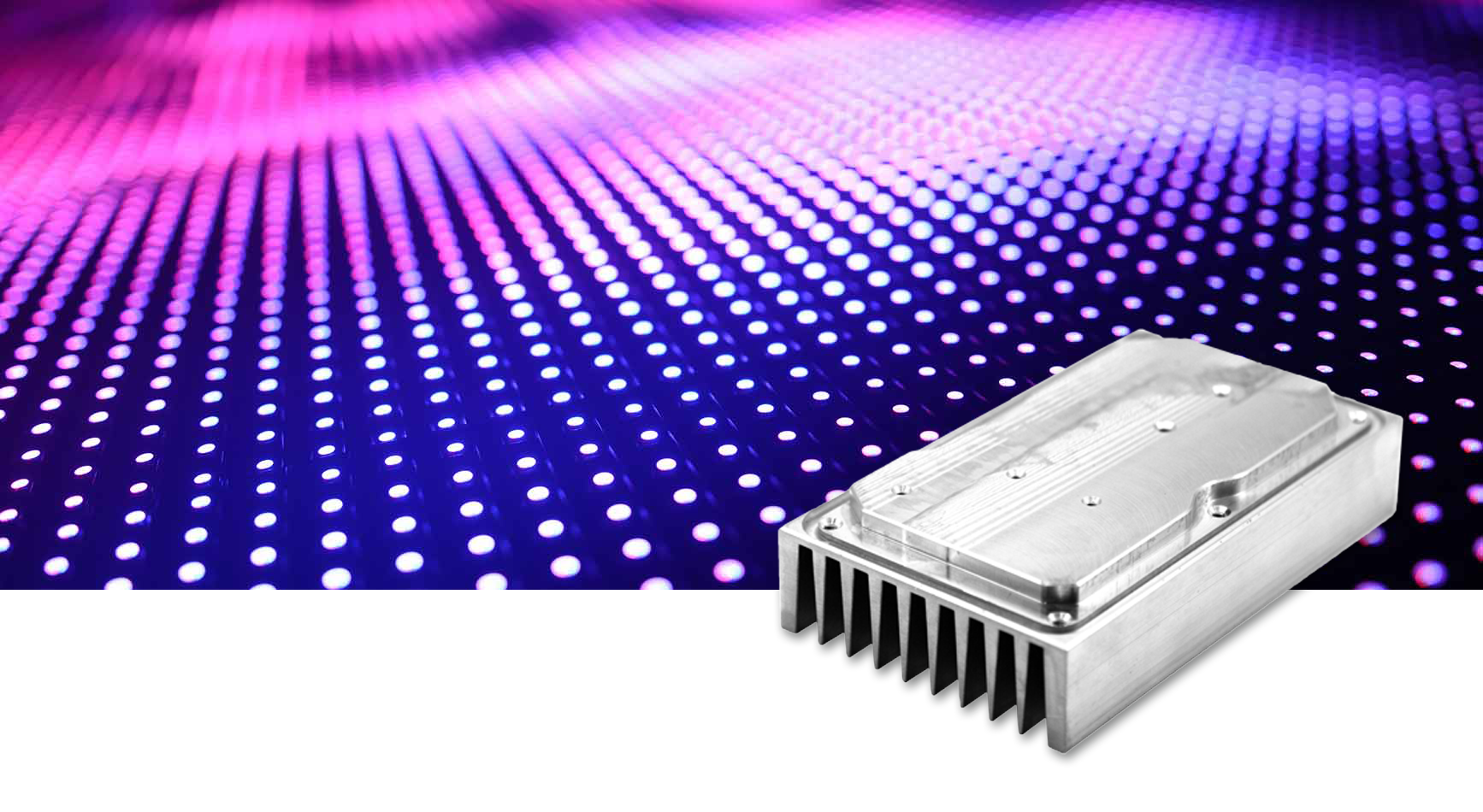

LEDs

The light output and light color of LEDs depend on the temperature of the LED unit. Only a constant temperature level will ensure the longevity of the light source. Heat sinks for high-performance LED lighting therefore fulfill important functions with regard to the performance, efficiency and service life of the LEDs. In the consumer sector, the cooling function is mainly covered by the housing parts, meaning no additional heat sink is required. Seifert electronic manufactures individual LED heat sinks for industrial or outdoor lighting as well as larger LED lights in the railroad sector.

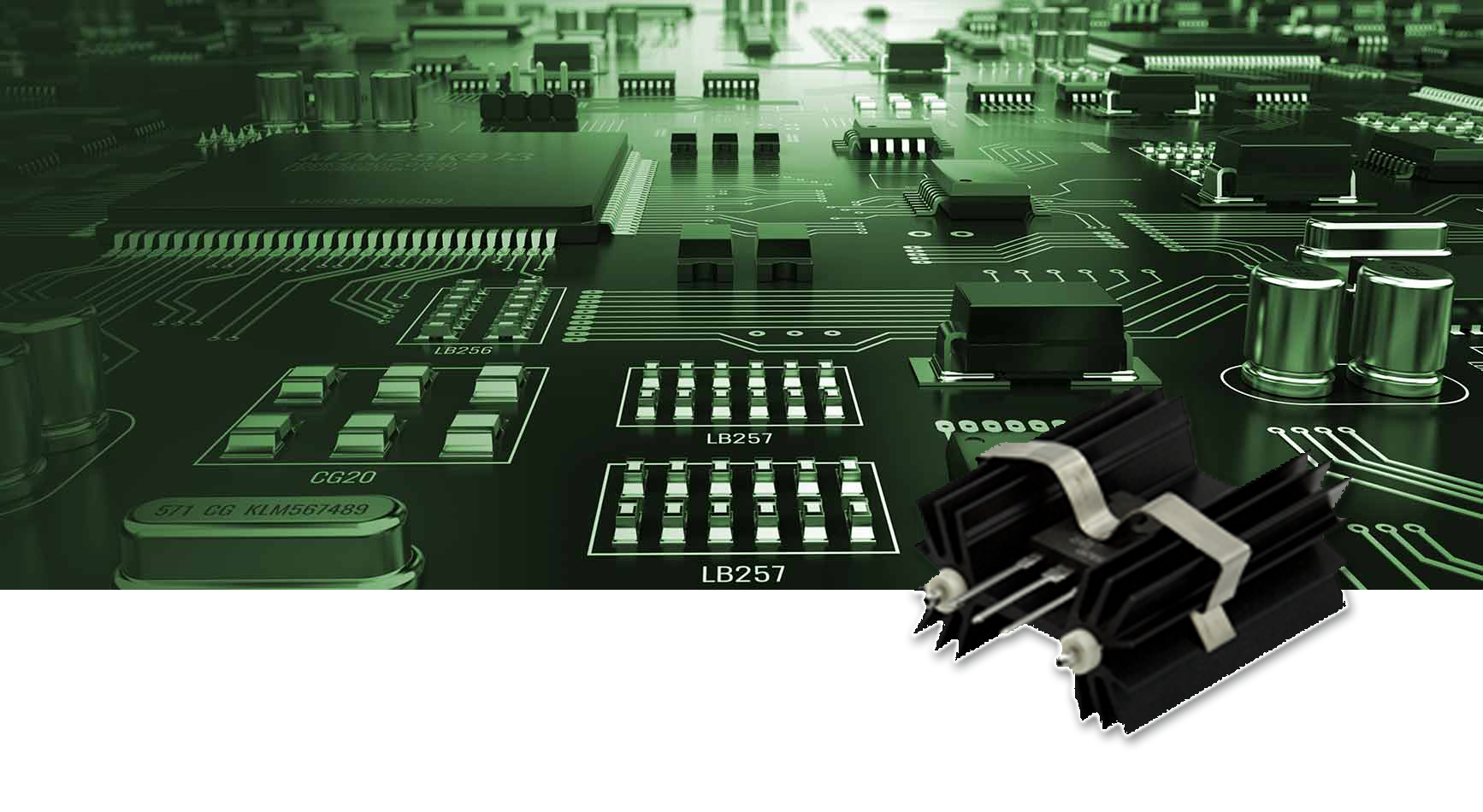

Printed circuit boards

The heat from components on printed circuit boards is mainly dissipated by natural convection and radiation. We offer a variety of different heat sink designs for this purpose. Heat sinks in the PCB area are usually black anodized so as to take advantage of the associated higher emission rate of blackbody surface radiation. The Seifert PC board heat sinks achieve high heat dissipation while optimizing the use of installation space and are available in all common fastening types.

Solar applications

The solar modules in photovoltaic systems produce direct current, which must be converted into alternating current by inverters before being fed into the public grid. In addition to this conversion, the inverters also perform control tasks for grid suppy and monitoring. The inverters therefore play a central part in the reliable operation of the solar installation. For high efficiency operation, the resulting power loss must be reliably dissipated. The high-performance heat sinks from Seifert are used for forced cooling in photovoltaic systems.

Converters

Frequency converters control the speed of electric motors by changing the voltage and frequency and thus enabling continuous variation of the motor speed. Their high power density requires an effective forced cooling, which can dissipate the high amounts of heat in a compact installation space. The Seifert high-performance fan units and the finned coolers of the Vario series perfectly meet these requirements and can be flexibly adapted to the respective requirements thanks to their modular design.