They are known to work best under pressure: presspack cells. When using these under very high currents and voltages, Seifert electronics offers heat sinks and mounting brackets for the right contact pressure in order to achieve optimum presspack cell cooling.

Presspack cells always take charge of the circuit where very high currents and voltages are present. This makes presspack cell cooling all the more important for a good electrical and thermal transition. For this to work, the connection between the individual presspack cells and the heat sinks is the most important factor in presspack cell cooling. Said connection must be made using the clamping force defined by the manufacturer.

With our Seifert heat sinks and the associated mounting brackets, also known as clamping brackets, we offer the professional equipment for the right contact pressure at all times in presspack cell cooling. This gives the structure a very long service life and the corresponding robustness.

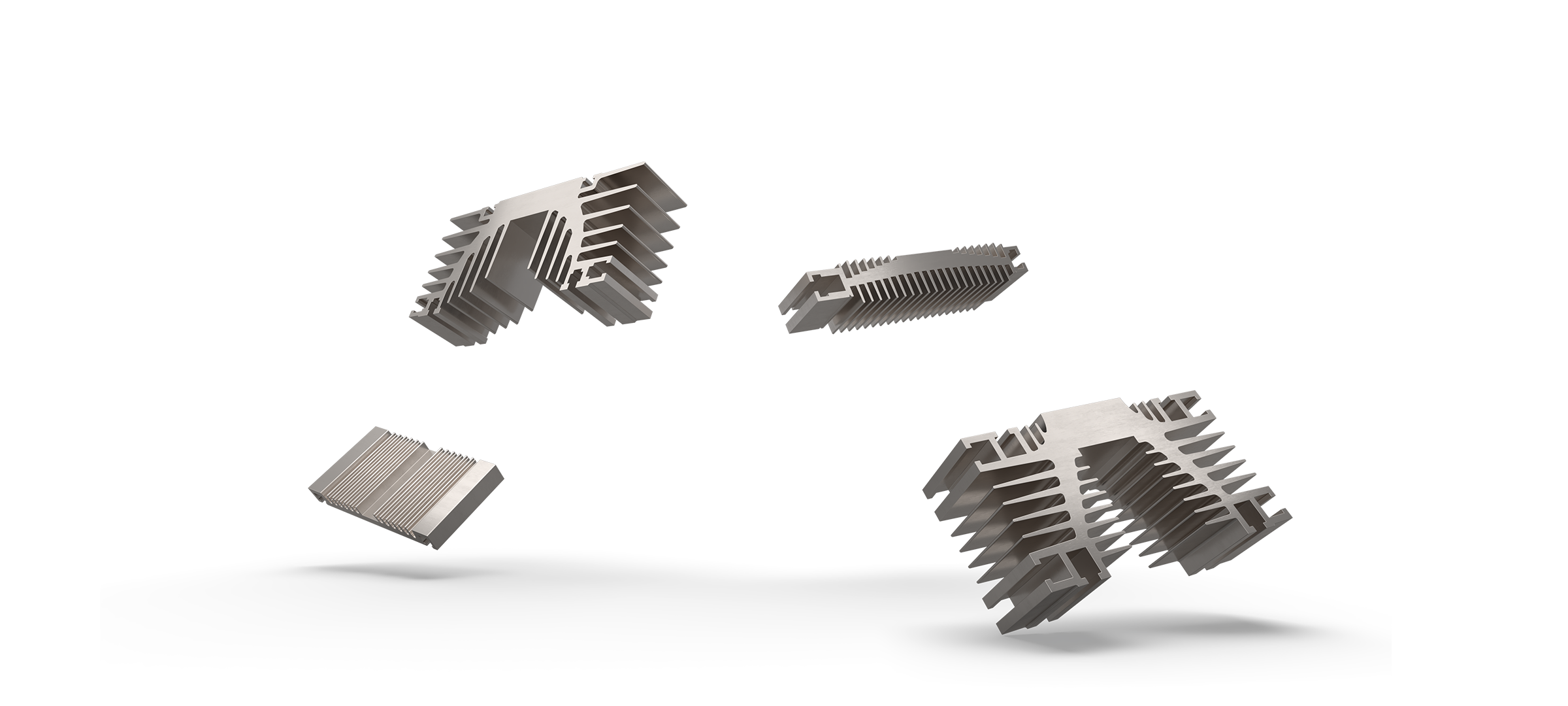

Profile heat sinks

Our cooling profiles for presspack cell cooling have a special geometry for the use of mounting brackets. Whether for the production of customized cooler geometries with non-standard dimensions or for the attachment of current bars – we weld it for you at Seifert electronic. Our profile heat sinks are fitted with screw channels in the profile as standard to allow easy attachment of current bars.

We create the hole patterns matching the individual mounting brackets in the face-milled heat sinks. We are also happy to carry out additional drilling and milling work for you as part of CNC machining. A large selection of variants for connecting the different heat sinks and presspack cells is available as standard in our range.

Variable clamping force

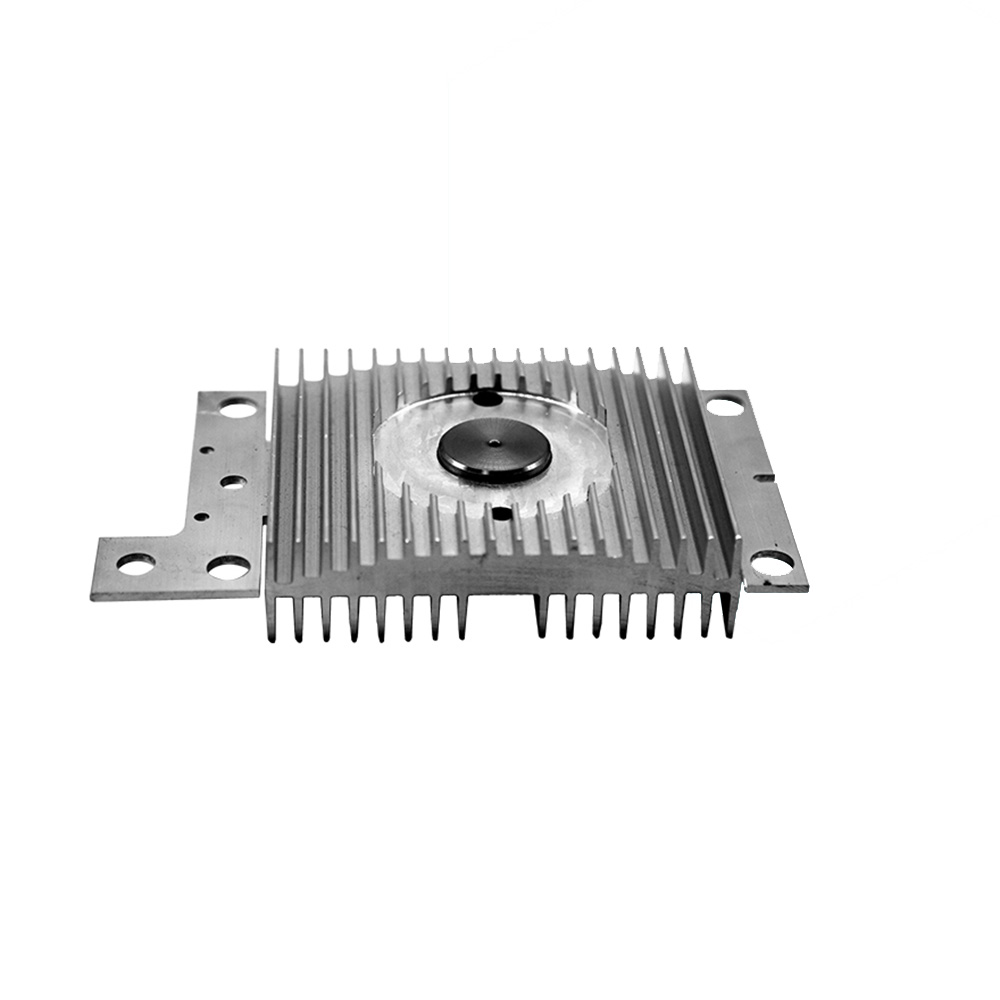

Our mounting brackets can be used to connect the cooling profiles to the presspack cells – they are clamped in place. And precisely according to the specified clamping force. The adjustment rings on the mounting brackets make it easy to set the necessary clamping force between the heat sinks and presspack cells during assembly and check it repeatedly. This keeps the desired contact pressure constant.

The mounting brackets can be adjusted to the desired clamping force, depending on the manufacturer’s specifications, and the screw length can be selected to suit the size of the presspack cells and heat sinks. There are also various options available for the necessary insulating material. It is important for the insulating tube to protrude into the upper heat sink and for the clamping path to remain free.

Using the selection tables for our mounting brackets for variable clamping force adjustment and different screw lengths, you should be able to find the right cooling profiles and mounting brackets for your presspack cells in our catalog. Feeling the pressure of a big selection and unsure which product is the right one for your application? Then get in touch.

We will be more than happy to advise you on how to properly put pressure on your presspack cells.